Please be informed that from now onwards our parent company Digital Surf is in charge of customer relations and sales and that the SPIP product is no more available for sale.

Try MountainsSPIP® for free

The good news is that many of the SPIP functions will continue in the MountainsSPIP® software and that all our SPIP customers having an active maintenance service are entitled to a MountainsSPIP® 8 license valid until the end of 2020, free of charge in addition to their SPIP license.

If you are eligible to benefit from this offer, the Digital Surf sales team will be in touch with you shortly to help you activate your free MountainsSPIP® license and assist with any questions you may have.

If you are having an active SPIP maintenance service we are still here to assist you and you are welcome to ask questions at support@imagemet.com.

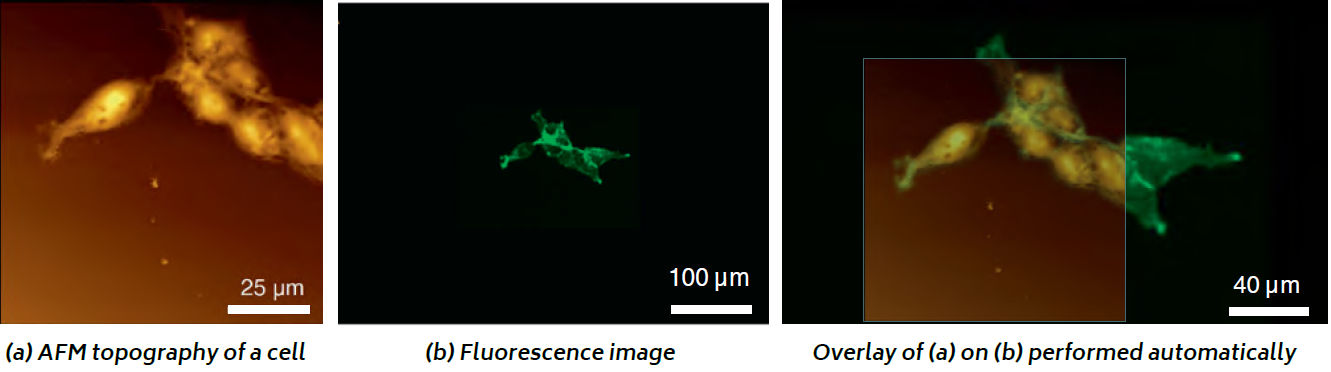

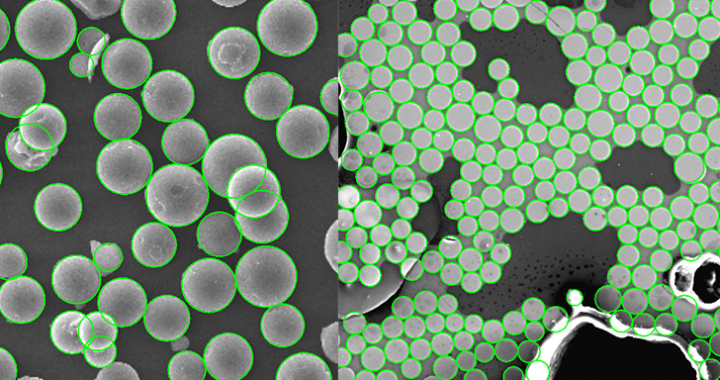

A free trial version of MountainsSPIP® is available for download at https://www.digitalsurf.com/free-trial/. To learn more about the features of MountainsSPIP® products please visit https://www.digitalsurf.com/software-solutions/scanning-probe-microscopy/

Thank you for an inspiring time

I would like to take this opportunity to thank all our valued SPIP users, – it has been a great pleasure to serve you with new software functions, which you inspired us to develop over the years. I wish you every success with MountainsSPIP®, which I am convinced will be the state-of-the-art SPM image analysis software for many years to come.

The future

The future mission of Image Metrology will be research and development of new algorithms and functions supporting continued improvements of MountainsSPIP® and we will be pleased to engage in projects together with research institutes in the field of SPM and related techniques. So, if you have ideas for such R&D projects you are most welcome to contact us via info@imagemet.com.

Best regards,

Jan Friis Jørgensen, CEO